Sigma One

One purpose. Weld.

A robust MIG/MAG inverter welding machine. Designed for light and heavy use in manufacturing companies of all sizes. Powerful, simple and reliable.

- High duty cycle - weld for many hours

- Produce high-quality welds

- Fast welding with pulse

- For continuous welding or occational use

One, that gets the job done

Sigma One’s powerful and reliable performance matches many different needs in professional manufacturing companies: from simple welding and maintenance projects to continuous welding in busy workshops. Use it for mild steel, stainless steel and aluminium.

Produce high-quality welds

With Sigma One, you get the essential programs and functions you need to produce strong, high-quality welds. The high versatility enables you to handle a wide range of materials and thicknesses.

You can increase precision and accuracy when welding both root passes and the additional layers. Sigma One can help you to succeed with your welding projects.

For occasional welding – light use

The lower amperages options for Sigma One are meant for repair, maintenance and other quickly done welding tasks in professional industries.

For the occasional welds and unexpected need for welding. It is great for small workshops or well-equipped maintenance departments.

Faster welding with pulse

Improve productivity even further with pulse process. The low heat input and spatter-free pulse welding lowers the risk of damaging the steel.

The process gives you a better control of the weld pool and a better weld.

For continuous welding – heavy use

The high duty cycle enables you to weld for many hours without any decrease of currents or compromising welding quality.

Weld as many meters per day as your tasks require. A team of welders can keep the productivity level at an absolute maximum.

Choose the One for you

Maintenance or Production

Sigma One 230/270

If welding is a sudden need

Sigma One 230/270 is developed for the occasional welds and unexpected need for welding. For small workshops or a well-equipped maintenance departments. A place where workers might not be full-time welders, but still need to produce excellent welds.

Adjusting the Sigma One 230/270 will be easy for each weld. Even if days pass in between them. The synergic welding programs with predefined settings help the occasional welders.

They do not have time to familiarise themselves with the welding machine for every use – and fear not, they do not have to. But, they will still get the job done.

Sigma One 300/400/500

If welding is your one purpose

Sigma One 300/400/550 is developed for use in busy welding productions. A place where the main aim is to keep the productivity level high. Where dedicated MIG/MAG welders spend hours and hours to fulfil their sole purpose: to weld.

Great craftsmanship is a result of passion, dedication, and attention to detail. Sigma One above 300 amps encourage dedication and focus, so welders can carry out efficient high-quality multipass welding.

Supervisors will experience great welding craftsmanship and see that their team of welders get the job done.

Design upgrade

Sigma One 230/270

This design upgrade is about quality, functionality and appeal. The dimples are gone so the MIGATRONIC logo can shine. The pure, dynamic expression of the rounded cabinet is a perfect fit for the mood of our time.

Configurations

Compact or Separate wirefeeding?

Sigma One Compact

Stay put

A compact welding machine is great if you want it to stay in a welding booth or be right next to the working table at all times. The length of the torch determines how far away from the welding machine, the welder can go.

Current range:

230/270/300/400/550

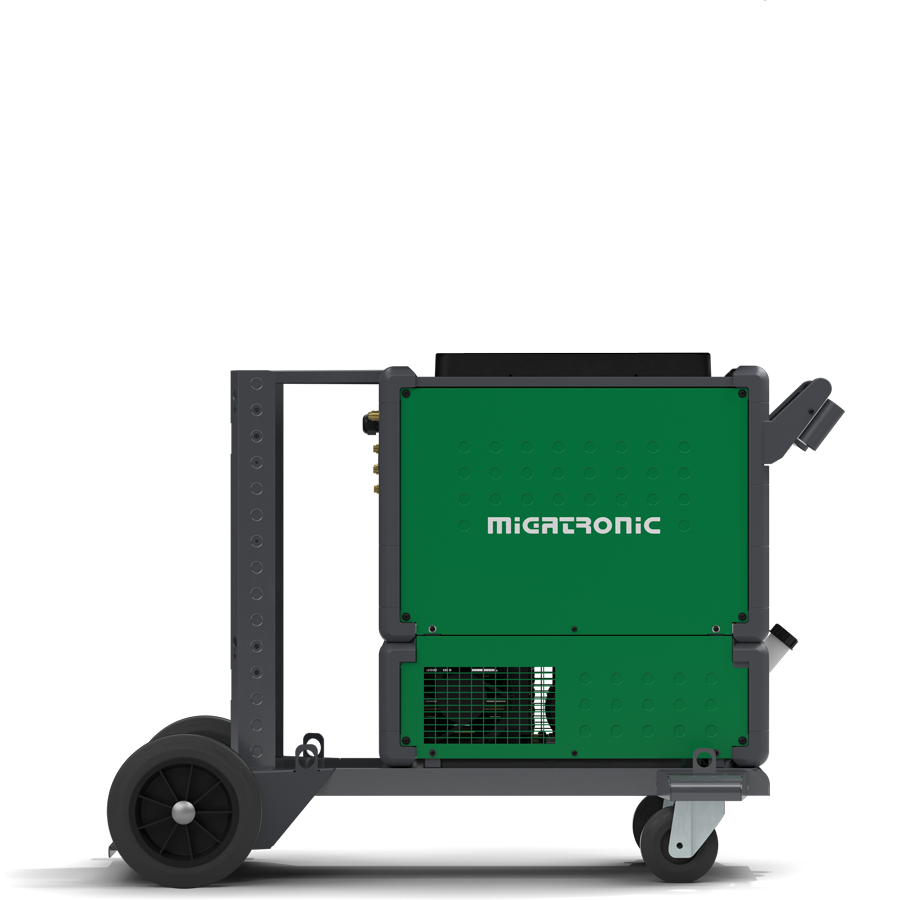

Sigma One Separate

Move around

Separate yourself from the power source with these ones. Go as far away from the power source as the intermediary cables allow. Move around large steel structures and plates while serving your sole purpose: to weld.

Current range:

300/400/550

Graphic control panel

Intuitive and easy to use

Easy to use for both welders and supervisors.

The graphic control panel is designed to be easy to understand. Users with limited experience with digital welding machine displays will quickly grasp this simple design. It is easy to find and adjust the core welding settings: amps, voltage and wire feed speed. It is great if you want well-known settings presented in a simple, yet visually compelling way.

The interface

Upgrade via SD-card

Lock specific settings

Features

Improve your welds

Miga Memory

Intelligent Gas Control (IGC®)

With IGC, the welding machine always uses the right amount of gas for every weld. It prevents over-consumption and gives you long-term savings.

The higher the amperage and the bigger the weld pool, the more gas you need. A traditional valve does not know this, but IGC® does. Gas synergy lines are preadjusted for gas and type of wire. It makes sure that your weld pool is always perfectly protected.

When you always have the optimum gas protection, there will be no holes, pores or impure welds. Reduce the risk of failures created by insufficient gas flow or gas turbulence. Improve the weld quality and reduce your gas bill at the same time. IGC® is an optional feature.

Torches

Every welder's closest ally

Welding cable

How far do you want to go?

Sigma One 230/270

Configuration possibilities

Welding torch: 3 - 4 meters

Sigma One Compact

Configuration possibilities

Welding torch: 3 - 6 meters

Sigma One Separate

Configuration possibilities

Welding torch: 3 - 6 meters

Interconnection cable: 1,5 - 30 meters

Service

Get peace of mind

Get serviced by our large service network

Our network of Authorized Service Partners across Europe is ready to support your welding production.

Authorized Service Partners have educated service technicians who are certified to perform professional

service and maintenance. They know your welding machine and their service vehicles are packed with

original spare parts, calibration measuring- and testing equipment.

Visit migatronic.com/service to find your nearby service partner

Extend the warranty - up to 5 years

You can be sure of high-quality products when you buy Migatronic. In addition to the warranty period of 2 years for new welding machines, you can extend the warranty up to 5 years. To maintain the extended warranty, a yearly service check is required. Register your newly purchased Sigma One on migatronic.com/warranty no later than 30 days from the

date of purchase. Then you get up to 5 years warranty on selected components.